|

|

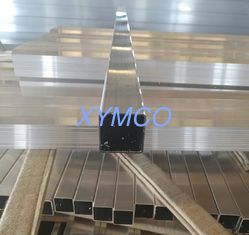

Magnesium Square Pipe Magnesium Square Tube AZ31 AZ61 magnesium alloy pipe AZ80 tube

Product Details:

Payment & Shipping Terms:

|

| Weldability: | Strong Weldments Up To 95% Of Parent Metal, With Minimal Porosity | High Srength: | Excellent Strength And Stiffness Per Unit Weight |

|---|---|---|---|

| Stability: | No Stress Relief After Machining; No Warps And Is Dent Resistant | Damping: | Absorbs Vibration For Longer Life, While Retaining Dimensional Stability |

| Non-magnetic: | Good For Electrical And Computer Applications | Light Weight: | Density Is 1.78, Less Than Steel Alloy 80% |

Magnesium Square Pipe Magnesium Square Tube AZ31 AZ61 magnesium alloy pipe AZ80 tube

Wrought Magnesium Alloy Specifications

Magnesium alloys have traditionally been specified by designers because of their favorable strength to weight ratios. Magnesium is approximately two thirds the density of aluminium and a quarter that of steel. Some of the more recently developed magnesium alloys have also improved resistance to corrosion and better all round mechanical properties, especially at elevated temperature.

The growing numbers of available magnesium alloys are divided into two groups: casting alloys and wrought alloys. Wrought product forms (described below) include both extruded sections and rolled sheet/plate along with tubes and forgings. Various heat treatments are used to attain maximum strength and machining of most magnesium alloys is excellent.

The specifications and alloy grades which XYCM can be complied with are as following Table:

| DESCRIPTION |

ASTM Alloy Designation & Temper |

ASTM | FEDERAL | AMS | ||

| AZ31B | Sheet - soft | AZ31B-O | B90 | QQ-M-44B | 4375 | |

| Sheet - half hard | AZ31B-H24 | B90 | QQ-M-44B | 4377 | ||

| Plate - soft | AZ31B-O | B90 | QQ-M-44B | 4375 | ||

| Plate - half hard | AZ31B-H24 | B90 | QQ-M-44B | 4377 | ||

| Plate- three quarters hard | AZ31B-H26 | B90 | QQ-M-44B | 4376 | ||

| Plate - Extra flat | AZ31B-O | -- | 4382 | |||

| Extruded bars & sections | AZ31B-F | B107 | QQ-M-31B | - | ||

| AZ61A | Extruded bas & sections & forging stock | AZ61A-F | B107 | QQ-M-31B | 4350 | |

| Extruded tube | AZ61A-F | B107 | WW-T-825B | - | ||

| Forgings | AZ61A-F | B91 | QQ-M-40B | - | ||

| AZ80A |

Extruded bars & sections |

precipitation treated | AZ80A-T5 | B107 | QQ-M-31B | - |

| As-extruded | AZ80A-F | B91 | QQ-M-31B | - | ||

| Forgings | precipitation treated | AZ80A-T5 | B91 | QQ-M-40B | 4360 | |

| As-extruded | AZ80A-F | B91 | QQ-M-40B | |||

| ZK60A |

Extruded bars & sections |

precipitation treated | ZK60A-T5 | B107 | QQ-M-31B | 4352 |

| As-extruded | ZK60A-F | B107 | QQ-M-31B | - | ||

| Forgings | precipitation treated | ZK60A-T5 | B91 | QQ-M-40B | 4362 | |

| As-extruded | ZK60A-F | B91 | QQ-M-40B | - | ||

| Magnesium Alloy Castings | AM50, AM60, A281, AZ91, EQ21, EZ33, EV31, WE43, WE54, ZE41 | |||||

![]()

Xi'an Yuechen Metal Products. Co., Ltd. (XYMCO) - a manufacturer specialized in the magnesium tooling plate, Magnesium alloy plate, magnesium alloy slab, magnesium alloy sheet, magnesium alloy bar, magnesium alloy tube, magnesium alloy billet, magnesium alloy rod, magnesium alloy rod, magnesium alloy pipe, magnesium welding wire, magnesium alloy profile, magnesium alloy forging, magnesium alloy casting, magnesium alloy machining part.

We comply with the specifications: AMS 4377G, AMS 4382, ASTM B90/B90M and ASTM B107.

Material grades: AZ31B, AZ61A, AZ80A, ZK60, AM50, AM60, AZ91, EQ21, EZ33, EV31, WE43, WE54 and ZE41.

Our main products and capacities are as follows:

1. Magnesium tooling plate: Max. Thickness: 300mm; Max. Width: 3000mm; Max. Length: 6000mm

2. Magnesium alloy slab: Max. Size: 400 x 1000 x 2500mm

3. Magnesium alloy sheet: Min. Thickness: 0.5mm; Max. Width: 600mm; Max. Length: 2000mm

4. Magnesium cast bar: Min. Diameter 90mm; Max. Diameter: 600mm; Max. Length: 6000mm

5. Magnesium extrusions:

Round tube: Max. OD 600mmx thickness 125mm Square tube: 430 x 430mm Flat bar: 920 x 160mm

U-Shape: 800 x 300mm Rectangular: 700 x 200mm

6. Magnesium alloy machined part according to customer’s design

7. Magnesium anode as per customer’s design

Our products already were exported to USA, Japan, Israel, India, Germany, Iran, Columbia, Italy and UK. Good quality, good price and good delivery.

Magnesium alloy pipe

Magnesium pipe

AZ31 magnesium pipe

AZ31B magnesium pipe

AZ31 magnesium alloy pipe

AZ31B magnesium alloy pipe

AZ31B-F magnesium pipe

AZ31B-F magnesium alloy pipe

Magnesium pipe AZ31

Magnesium pipe AZ31B

Magnesium alloy pipe AZ31

Magnesium alloy pipe AZ31B

Magnesium pipe AZ31B-F

Magnesium alloy pipe AZ31B-F

AZ61 magnesium pipe

AZ61A magnesium pipe

AZ61 magnesium alloy pipe

AZ61A magnesium alloy pipe

AZ61-F magnesium pipe

AZ61-F magnesium alloy pipe

AZ61A-F magnesium pipe

AZ61A-Fmagnesium alloy pipe

Magnesium pipe AZ61

Magnesium pipe AZ61A

Magnesium alloy pipe AZ61

Magnesium alloy pipe AZ61A

Magnesium alloy pipe AZ61-F

Magnesium alloy pipe AZ61A-F

AZ80 magnesium pipe

AZ80A magnesium pipe

AZ80 magnesium alloy pipe

AZ80A magnesium alloy pipe

AZ80-F magnesium pipe

AZ80A-F magnesium alloy pipe

Az80A-T5 magnesium pipe

AZ80A-T5 magnesium alloy pipe

Magnesium pipe AZ80

Magnesium pipe AZ80A

Magnesium alloy pipe AZ80

Magnesium alloy pipe AZ80A

Magnesium pipe AZ80-F

Magnesium alloy pipe AZ80A-F

Magnesium pipe AZ80A-T5

Magnesium alloy pipe AZ80A-T5

ZK60 magnesium pipe

AZ80A magnesium pipe

ZK60 magnesium alloy pipe

AZ80A magnesium alloy pipe

ZK60-F magnesium pipe

AZ80A-F magnesium alloy pipe

AZ80A-T5 magnesium pipe

AZ80A-T5 magnesium alloy pipe

Magnesium pipe ZK60

Magnesium pipe AZ80A

Magnesium alloy pipe ZK60

Magnesium alloy pipe AZ80A

Magnesium pipe ZK60-F

Magnesium alloy pipe AZ80A-F

Magnesium pipe AZ80A-T5

Magnesium alloy pipe AZ80A-T5

AZ91 magnesium pipe

AZ91D magnesium pipe

AZ91 magnesium alloy pipe

AZ91D magnesium alloy pipe

AZ91-F magnesium pipe

AZ91D-F magnesium alloy pipe

Magnesium pipe AZ91

Magnesium pipe AZ91D

Magnesium alloys are the lightest metal structure material for engineering applications. In the past years, engineers have taken a great interest in magnesium alloys in the automotive, aerospace, weapons, electronic and other fields, because of their low density, high specific strength and stiffness, good damping characteristics, as well as an excellent durability. Especially in the field of automobile industry, magnesium alloys have replaced the steel, cast iron and even aluminum alloys (Magnesium is the lightest of all structural metals, aluminum being 1.5 times heavier and steel being up to four times heavier), because they can reduce the weight of vehicles, so that significantly contributes to fuel economy and reducing CO2 emissions.

AZ31 Magnesium alloy is the most ductile and the most popular amongst AZ shaped alloys (Mg-Al-Zn group). Soft as it is, this alloy offers good combination of strength and ductility for structural application after deformation with severe reductions.

Diverse uses including aircraft fuselage, concrete tools, cell phone, camera, notebook computer cases and textile machinery.

The AZ31 alloy shaped magnesium tooling plate has the many benefits and special characteristics which gives the AZ31 many advantages like:

Absorbs vibration for much more lifetime, while keeping dimensional stability, 4 to 5 times greater tool life.

Up to 5 times more machinable than rolled aluminum, machine dry, without oil or chemicals, easier handling saves time and energy, eliminates surface machining, with no stress relief after machining process.

No warps and is dent resistant, strong weldments – up to 95% of parent metal, with minimum porosity, made for easy cleaning, with wide variety of chemical treatments exists for corrosion protection, alteration of surface appearance, and to provide a base for painting.

Due to its good specifications, AZ31 magnesium alloy can be used in all kinds of fields.

Magnesium alloy thick plate are used to make satellites ,lunar landing aircraft bases, exterior panel of missile and rocket and the empennage of missile and plane.

Magnesium alloy middle board are used to make the auxiliary tank, side board and other structure of battle plane.

Cast sheet of magnesium alloy:

The magnesium alloys are used on the train for vibration attenuation, seat and couchette framework lining board and goods shelf.

The wide width usually requests between 1200-2000mm, and thickness between 1 and 1.5mm on cars’ front and rear panels, door panels. The shell of 3C product, computer, mobile hard disk, CD, camera, acoustics, cell phone.

Magnesium etching has replaced copper plate in printing and printing plate industry, and average thickness of the plate is 5mm.

Magnesium has been continuously used in electric tool and sport equipment.

Magnesium sheet and plate AZ31 alloy has applications in medium strength service at temperatures below 150C.

Mechanical Properties

Elongation at break ( % ) – 15

Hardness – Brinell – 73

Modulus of elasticity ( GPa ) – 45

Tensile strength ( MPa ) – 290

Physical Properties

Density ( g cm-3 ) – 1.8

Melting point ( C ) – 605-630

-

Magnesium pipe AZ31B / AZ80A / AZ61A pipe ZK60A AZ63 AZ91 M1A magnesium alloy pipe tube ASTM standard

-

Magnesium pipe tube ZK60 ZK60A High Strength Magnesium Alloy Profile Magnesium Extruded Tube

-

Customized Cold drawn High strength Magnesium pipe AZ31 AZ80 wire bar/rod/billet AZ61 ZK60 Magnesium tubing for sports

-

Magnesium pipe ZK60-F magnesium alloy pipe Magnesium alloy pipe AZ80A-T5 as per ASTM B107/B107M-13

-

Magnesium alloy pipe ZK60 magnesium extruded pipe thick wall Magnesium pipe AZ80A-T5 as per ASTM B107/B107M-13

-

Extruded ZK60-F magnesium pipe ZK60 magnesium alloy pipe AZ61A Magnesium alloy pipe AZ80A-T5 as per ASTM B107/B107M-13