|

|

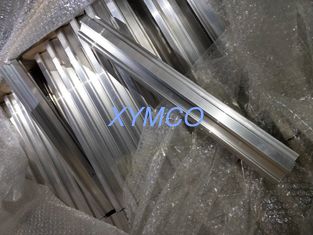

Magnesium AZ31 pipe / AZ31B tube Magnesium extruded pipe Magnesium metal tube Non-magnetic

Product Details:

Payment & Shipping Terms:

|

| Non-magnetic: | Good For Electrical And Computer Applications | Unit Volume Yield: | Greater Amount Of Finished Magnesium Material Obtained, Pound For Pound |

|---|---|---|---|

| Non-galling: | Sound And Rugged Surface, Offering A Low Coefficient Of Friction And Minimum Wear | Weldability: | Strong Weldments Up To 95% Of Parent Metal, With Minimal Porosity |

| Light Weight: | Two Thirds The Density Of Aluminium And A Quarter That Of Steel | Applications:: | Jigs, Fixtures, Optical Benches, Vibration Test Equipment And Inspection Gauges |

Magnesium AZ31 pipe / AZ31B tube Magnesium extruded pipe Magnesium metal tube Non-magnetic

Wrought Magnesium Alloy Specifications

Magnesium alloys have traditionally been specified by designers because of their favorable strength to weight ratios. Magnesium is approximately two thirds the density of aluminium and a quarter that of steel. Some of the more recently developed magnesium alloys have also improved resistance to corrosion and better all round mechanical properties, especially at elevated temperature.

The growing numbers of available magnesium alloys are divided into two groups: casting alloys and wrought alloys. Wrought product forms (described below) include both extruded sections and rolled sheet/plate along with tubes and forgings. Various heat treatments are used to attain maximum strength and machining of most magnesium alloys is excellent.

The specifications and alloy grades which XYCM can be complied with are as following Table:

| DESCRIPTION |

ASTM Alloy Designation & Temper |

ASTM | FEDERAL | AMS | ||

| AZ31B | Sheet - soft | AZ31B-O | B90 | QQ-M-44B | 4375 | |

| Sheet - half hard | AZ31B-H24 | B90 | QQ-M-44B | 4377 | ||

| Plate - soft | AZ31B-O | B90 | QQ-M-44B | 4375 | ||

| Plate - half hard | AZ31B-H24 | B90 | QQ-M-44B | 4377 | ||

| Plate- three quarters hard | AZ31B-H26 | B90 | QQ-M-44B | 4376 | ||

| Plate - Extra flat | AZ31B-O | -- | 4382 | |||

| Extruded bars & sections | AZ31B-F | B107 | QQ-M-31B | - | ||

| AZ61A | Extruded bas & sections & forging stock | AZ61A-F | B107 | QQ-M-31B | 4350 | |

| Extruded tube | AZ61A-F | B107 | WW-T-825B | - | ||

| Forgings | AZ61A-F | B91 | QQ-M-40B | - | ||

| AZ80A |

Extruded bars & sections |

precipitation treated | AZ80A-T5 | B107 | QQ-M-31B | - |

| As-extruded | AZ80A-F | B91 | QQ-M-31B | - | ||

| Forgings | precipitation treated | AZ80A-T5 | B91 | QQ-M-40B | 4360 | |

| As-extruded | AZ80A-F | B91 | QQ-M-40B | |||

| ZK60A |

Extruded bars & sections |

precipitation treated | ZK60A-T5 | B107 | QQ-M-31B | 4352 |

| As-extruded | ZK60A-F | B107 | QQ-M-31B | - | ||

| Forgings | precipitation treated | ZK60A-T5 | B91 | QQ-M-40B | 4362 | |

| As-extruded | ZK60A-F | B91 | QQ-M-40B | - | ||

| Magnesium Alloy Castings | AM50, AM60, A281, AZ91, EQ21, EZ33, EV31, WE43, WE54, ZE41 | |||||

![]()

Specifications of Magnesium alloy(composition%) :

| Model Number of Magnesium | Mg | Al | Zn | Mn | Si | Fe | Cu | Ni |

| AZ31B | Balance | 2.2∼3.5 | 0.6∼1.4 | 0.20∼1.0 | 0.08 | 0.003 | 0.01 | 0.05 |

| AZ61A | Balance | 5.8∼7.2 | 0.40∼1.5 | 0.15∼0.50 | 0.10 | 0.005 | 0.05 | 0.005 |

| AZ61M | Balance | 5.5∼7.0 | 0.50∼1.5 | 0.15∼0.50 | 0.10 | 0.05 | 0.05 | 0.005 |

| AZ80A | Balance | 7.8∼9.2 | 0.20∼0.8 | 0.12∼0.50 | 0.10 | 0.005 | 0.05 | 0.005 |

| AZ91D | Balance | 8.5∼9.5 | 0.45∼0.9 | 0.17∼0.40 | 0.08 | 0.004 | 0.02 |

0.001

|

![]()

Our main products and capacities are as follows:

1. Magnesium tooling plate: Max. Thickness: 300mm; Max. Width: 3000mm; Max. Length: 6000mm

2. Magnesium alloy slab: Max. Size: 400 x 1000 x 2500mm

3. Magnesium alloy sheet: Min. Thickness: 0.5mm; Max. Width: 600mm; Max. Length: 2000mm

4. Magnesium cast bar: Min. Diameter 90mm; Max. Diameter: 600mm; Max. Length: 6000mm

5. Magnesium extrusions:

Round tube: Max. OD 600mmx thickness 125mm Square tube: 430 x 430mm Flat bar: 920 x 160mm

U-Shape: 800 x 300mm Rectangular: 700 x 200mm

6. Magnesium alloy machined part according to customer’s design

7. Magnesium anode as per customer’s design

![]()

-

AZ31 AZ80 Magnesium extrusion alloy pipe/tube/profile/bar/rod/billet AZ61 ZK60 Customized Magnesium Extrusion Profile

-

Magnesium alloy tube AZ31 Mag tube ligh weight AZ31B-F magnesium alloy pipe for drone

-

Magnesium alloy pipe AZ80A-F Magnesium pipe ZK60 Magnesium tube as per ASTM B107/B107M-13

-

Magnesium alloy pipe tube AZ31 magnesium rod billet bar sheet plate for Full magnesium doors

-

Extruded Magnesium alloy pipe AZ80A-T5 grade magnesium alloy tube AZ80A-F magnesium alloy rod billet bar wire AZ80A

-

Magnesium alloy pipe Magnesium tube ZK60A-T5 tube ZK60A-F pipe with high strength