|

|

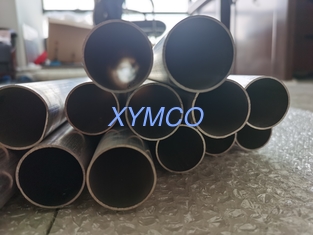

Extruded ZK60A magnesium alloy pipe AZ80A magnesium alloy tube rod bar billet AZ31B AZ61A magnesium tube ASTM standard

Product Details:

Payment & Shipping Terms:

|

| Specification:: | AMS 4377G, AMS 4382, ASTM B90/B90M And ASTM B107. | Specific Heat:: | 1040 Jkg-1k-1 |

|---|---|---|---|

| Electrical Resistivity:: | 92nΩm | Melting Range:: | 566 - 632°C |

| Hardness: | H24 Temper: 83 Rockwell E | STRENGTH: | Excellent Strength And Stiffness Per Unit Weight. |

| WEIGHT: | Easier Handling Saves Energy And Time. | Weldability: | Excellent With Gas Shielded Arc |

| Ultrasonic Inspection To: | AMS 2154 Class B, A | Material Grade:: | AZ31B, AZ61A, AZ80A, ZK60, AM50, AM60, AZ91, EQ21, EZ33, EV31, WE43, WE54 And ZE41. |

Extruded ZK60A magnesium alloy pipe AZ80A magnesium alloy tube rod bar billet AZ31B AZ61A magnesium tube ASTM standard

![]()

Magnesium alloy tube/pipe

Xi'an Yuechen Metal Products. Co., Ltd. (XYMCO) has manufactured magnesium alloy tube/pipe from 1995. We have production capacity with 1250 tonne press, 2500 tonne press and 3600 tonne press in house, our subcontract company has the 8000 tonne press and 10000 tonne press so that we can supply our customers big section extrusions.

Our extrusion capacity is as follows:

Round tube: Max. OD600mmx thickness 125mm

Square tube: 430 x 430mm

Flat bar: 920 x 160mm

U-Shape: 800 x 300mm

Rectangular: 700 x 200mm

Available extrusion alloys:

AZ31B, AZ61A, AZ80A, M1A, ZK60A, Pure Magnesium and Custom alloys

Heat treatment is available as per customer’s application.

Specification:

ASTM B107/B107M-13

GB standard

Existing Extrusion Mould of tube:

| OD | Wall thickness (mm) |

| 22 | 1.5 |

| 22 | 2 |

| 24.5 | 2 |

| 25 | 1.5 |

| 25 | 2 |

| 25 | 2.5 |

| 25 | 3 |

| 25 | 3.5 |

| 26 | 1.2 |

| 26 | 1.6 |

| 27 | 3.5 |

| 28 | 3 |

| 28.5 | 3 |

| 28.6 | 2.5 |

| 29 | 5 |

| 38 | 2.65 |

| 38.1 | 6 |

| 40 | 1.25 |

| 44 | 5.5 |

| 51 | 8 |

| 64 | 5.6 |

| 69 | 6 |

| 70 | 4 |

| 75 | 6.5 |

| 104 | 4.5 |

| 50 | 5 |

| 30 | 3 |

| 42 | 5 |

| 45 | 13.5 |

| 34.9 | 1.25 |

| 20 | 1.5 |

| 36 | 2.5 |

| 38 | 2.5 |

| 38.1 | 6 |

| 38.1 | 1.8 |

| 40 | 3.25 |

| 40 | 4 |

| 42 | 4 |

| 42 | 6 |

| 44 | 1.25 |

| 44 | 1.8 |

| 44.5 | 2 |

| 45 | 2 |

| 50 | 2 |

| 50.8 | 1.48 |

| 50.8 | 1.65 |

| 51 | 2 |

| 9 | 1 |

| 10.4 | 1 |

| 10.4 | 2.4 |

| 13.2 | 1 |

| 13.5 | 1.25 |

| 16 | 1 |

| 19 | 1.2 |

| 22 | 1.2 |

| 22 | 2 |

| 145 | 7 |

| 65 | 15 |

| 170 | 20 |

| 132 | 14.5 |

![]()

Our Advantages:

| Extremely strong and light weight | Nice looking with competitive |

| Corrosion resistance | Abrasion- resistance |

| Low coefficient thermal expansion | Impact resistance |

| durable and long-lasting | Environmentally safe |

| Non-magnetic electromagnetic | Wide temperature range use |

| Ease of fabrication & installation | Excellent fatigue resistance |

| Without residual glue after remove | Convenient to construct |

| Good resilience | Convenient to pack and transport |

| Tensile strength | UV resistance |

![]()

Our Services:

1. Small order quantity available

2. Professional engineering team and sales team

3. Payment: T/T & Western Union

4. OEM/ODM Supporttable

5. Free samples provided

6. Competitive price and high quality

FAQ:

1. Q: Are you a factory or trading company?

A: We are direct manufacturer located in Xi'an, Shaanxi province, and have our equipment!

2. Q: Are your products customized?

A: Yes,the products in the website are only the common type or the previous types, we can supply the new products according to your requirements or drawings.

3. I do not know how to use your product ?

Do not worry ! We can supply technical guidance together with products.

4. Q: How can I get some samples?

A: Several samples are freely offered for buidling the business long-term relationships and letting our customers believing the quality of our products.

-

AZ31 AZ80 Magnesium extrusion alloy pipe/tube/profile/bar/rod/billet AZ61 ZK60 Customized Magnesium Extrusion Profile

-

Magnesium alloy tube AZ31 Mag tube ligh weight AZ31B-F magnesium alloy pipe for drone

-

Magnesium alloy pipe AZ80A-F Magnesium pipe ZK60 Magnesium tube as per ASTM B107/B107M-13

-

Magnesium alloy pipe tube AZ31 magnesium rod billet bar sheet plate for Full magnesium doors

-

Extruded Magnesium alloy pipe AZ80A-T5 grade magnesium alloy tube AZ80A-F magnesium alloy rod billet bar wire AZ80A

-

Magnesium alloy pipe Magnesium tube ZK60A-T5 tube ZK60A-F pipe with high strength