|

|

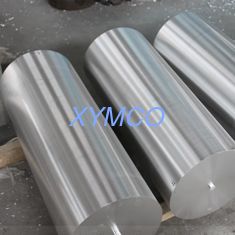

Extruded High strength AZ80 magnesium billet AZ80A alloy bar AZ80A-T5 magnesium rod AZ80A-F welding wire no warp

Product Details:

Payment & Shipping Terms:

|

| Shape: | Round, Square, Rectangular | High Strength: | Excellent Strength And Stiffness Per Unit Weight. |

|---|---|---|---|

| Good Anti Electromagnetic Interference And Shield: | Stable Dimensionally And Easy Processing. | TOOLING: | 4 To 5 Times Greater Tool Life. |

| Ligh Weight: | Easier Handling Saves Energy And Time. | DAMPING: | Absorbs Vibration For Longer Life, While Retaining Dimensional Stability |

| COSTS: | Machine Dry, Without Oil Or Chemicals. | Thermal Conductivity:: | 76.9Wm-1k-1 |

| Density:: | 1.81 | Electrical Resistivity:: | 92nΩm |

| Modulus Of Elasticity:: | 45 X 109Pa |

Magnesium alloy rod, magnesium alloy bar, magnesium alloy billet

XYMCO has manufactured magnesium alloy rod/bar from 1995. We have production capacity with 1250 tonne press, 2500 tonne press and 3600 tonne press in house, our subcontract company has the 8000 tonne press and 10000 tonne press so that we can supply our customers big section extrusions.

Our extrusion capacity is as follows:

Round tube: Max. OD600mmx thickness 125mm

Square tube: 430 x 430mm

Flat bar: 920 x 160mm

U-Shape: 800 x 300mm

Rectangular: 700 x 200mm

Available extrusion alloys:

AZ31B, AZ61A, AZ80A, M1A, ZK60A, Pure Magnesium and Custom alloys

Heat treatment is available as per customer’s application.

Specification:

ASTM B107/B107M-13

GB standard

Existing extrusion mould of rod/bar:

Dia. 12mm, Dia. 15mm, Dia. 20mm, Dia. 30mm, Dia. 40mm, Dia. 50mm, Dia. 60mm, Dia. 70mm, Dia. 80mm, Dia. 90mm, Dia. 100mm, Dia. 140mm, Dia. 165mm, Dia. 170mm, Dia. 210mm

Applications of our extruded products:

The special characteristics of magnesium such as its light weight and damping capacity make it a material that is readily used in several different applications.

![]()

Automotive

| Engine blocks | Steering column parts | Seat components |

| Bed plates | Brake and pedal brackets | Roof panels |

| Transmission houses | Airbag retainers | Fuel tank covers |

| Transfer cases | Radio frames + heatsinks | Engine hoods |

| Head covers | Radio covers | Rear deck lids |

| Oil pans | Mirror brackets | Full magnesium doors |

| Knee bolsters | Door handles | Wheels |

| Steering wheels | Front ends | Radiator supports |

Sport and Leisure

| Luggage frames | Suit cases | Tennis rackets |

| Bicycle frames | Camping equipment | Snowshoes |

| Mountain bike frames | Eyewear frames | Bull floats |

Common applications

| Cellular phones | Multi-media housings | Camcorders |

| Antenna housing | Camera Housings | Electric shavers |

| Loudspeaker frames | Projector frames | Printers |

| Laptop Housings | Batteries | Headphones |

| Train Seats | Aviation components | Turbine engines |

| Truss constructions | Cargo floors | Powertools |

| Chain saws | Concrete trowels | Wall saws |

| Ladders | Scaffoldings | Shelves |

![]()

XIAN YUECHEN METAL PRODUCTS CO., LTD. (XYMCO) is one of the leading manufacturer of magnesium alloy products located in Xincheng Hi-Tech Industry Estate, Xi’an, Shaanxi, China, who is specialized in the development, manufacture and supply of magnesium alloy products worldwide included magnesium tooling plate, magnesium alloy plate, magnesium alloy sheet, magnesium alloy slab, magnesium alloy bar, magnesium alloy billet, magnesium alloy rod, magnesium alloy tube, magnesium alloy pipe, magnesium alloy profile, magnesium welding wire, magnesium alloy extrusion, magnesium alloy stamping, magnesium alloy casting, magnesium alloy forging and semi - fabricated component according to customer’s design.

We comply with the specifications:

GB5153-03, GB5154-04, AMS4377G, ASTM B90/B90M-15, MIL-DTL 32333, MIL-T-38749, QQ-M-44B, ASTM B107/B107M-13 and ASTM B91-97

Material grades: AZ31B, AZ61A, AZ80A, AZ91D, AZ41M, ZK60, AM50, AM60, ZM21, MIA, ME20M, EQ21, WE43, WE54, ZE41, etc.

Our main products and capabilities are as follows:

1. Magnesium tooling plate: Max. Thickness: 300mm; Max. Width: 2000mm; Max. Length: 6000mm

2. Magnesium alloy cast slab: Max. Size: 400 x 1000 x 3000mm

3. Magnesium alloy sheet: Min. Thickness: 0.5mm; Max. Width: 600mm; Max. Length: 2000mm

4. Magnesium cast billet: Min. Diameter 90mm; Max. Diameter: 600mm; Max. Length: 6000mm

5. Magnesium alloy extruded wire: Dia.1.0mm – 8.0mm in spool.

6. Magnesium alloy extruded rod: Min. Dia. 8mm; Max. Diameter: 450mm; Max. Length: 3000mm

7. Magnesium extrusions:

Round tube: Max. OD600mmx thickness 125mm

Square tube: 430 x 430mm

Flat bar: 920 x 160mm

U-Shape: 800 x 300mm

Rectangular: 700 x 200mm

8. Magnesium-Lithium Alloy rod, sheet, plate and tube.

XIAN YUECHEN METAL PRODUCTS CO., LTD. (XYMCO) is able to mass produce LZ91, LA91, LA141, MA18 and MA21 magnesium lithium alloys in the form of rectangular or round shape ingot by vacuum melting techniques, and mass produce MgLi wrought alloys and its products of magnesium lithium alloy slab, magnesium lithium alloy bock, magnesium lithium alloy plate, magnesium lithium alloy sheet, magnesium lithium alloy foil, magnesium lithium alloy strip, magnesium lithium alloy coil, magnesium lithium alloy billet, magnesium lithium alloy rod, magnesium lithium alloy bar, magnesium lithium alloy tube, magnesium lithium alloy pipe, magnesium lithium alloy wire, magnesium lithium alloy profile by casting, forging, extrusion and hot rolling process. XYMCO also produces the customized sizes (non standard sizes) magnesium lithium alloy materials and its products according to customers’ requirements.

NPFC - MIL-M-46130 Magnesium-Lihium Alloy Plate, sheet and forgings (LA141A, LS141A and LZ145A)

Magnesium alloys are the lightest metal structure material for engineering applications. In the past years, engineers have taken a great interest in magnesium alloys in the automotive, aerospace, weapons, electronic and other fields, because of their low density, high specific strength and stiffness, good damping characteristics, as well as an excellent durability. Especially in the field of automobile industry, magnesium alloys have replaced the steel, cast iron and even aluminum alloys (Magnesium is the lightest of all structural metals, aluminum being 1.5 times heavier and steel being up to four times heavier), because they can reduce the weight of vehicles, so that significantly contributes to fuel economy and reducing CO2 emissions.

AZ31 Magnesium alloy is the most ductile and the most popular amongst AZ shaped alloys (Mg-Al-Zn group). Soft as it is, this alloy offers good combination of strength and ductility for structural application after deformation with severe reductions.

Diverse uses including aircraft fuselage, concrete tools, cell phone, camera, notebook computer cases and textile machinery.

The AZ31 alloy shaped magnesium tooling plate has the many benefits and special characteristics which gives the AZ31 many advantages like:

Absorbs vibration for much more lifetime, while keeping dimensional stability, 4 to 5 times greater tool life.

Up to 5 times more machinable than rolled aluminum, machine dry, without oil or chemicals, easier handling saves time and energy, eliminates surface machining, with no stress relief after machining process.

No warps and is dent resistant, strong weldments – up to 95% of parent metal, with minimum porosity, made for easy cleaning, with wide variety of chemical treatments exists for corrosion protection, alteration of surface appearance, and to provide a base for painting.

Due to its good specifications, AZ31 magnesium alloy can be used in all kinds of fields.

Magnesium alloy thick plate are used to make satellites ,lunar landing aircraft bases, exterior panel of missile and rocket and the empennage of missile and plane.

Magnesium alloy middle board are used to make the auxiliary tank, side board and other structure of battle plane.

Cast sheet of magnesium alloy:

The magnesium alloys are used on the train for vibration attenuation, seat and couchette framework lining board and goods shelf.

The wide width usually requests between 1200-2000mm, and thickness between 1 and 1.5mm on cars’ front and rear panels, door panels. The shell of 3C product, computer, mobile hard disk, CD, camera, acoustics, cell phone.

Magnesium etching has replaced copper plate in printing and printing plate industry, and average thickness of the plate is 5mm.

Magnesium has been continuously used in electric tool and sport equipment.

Magnesium sheet and plate AZ31 alloy has applications in medium strength service at temperatures below 150C.

Mechanical Properties

Elongation at break ( % ) – 15

Hardness – Brinell – 73

Modulus of elasticity ( GPa ) – 45

Tensile strength ( MPa ) – 290

Physical Properties

Density ( g cm-3 ) – 1.8

Melting point ( C ) – 605-630

Our Services:

1. Small order quantity available

2. Professional engineering team and sales team

3. Payment: T/T & Western Union

4. OEM/ODM Supporttable

5. Free samples provided

6. Competitive price and high quality

![]()

Our Services:

1. Small order quantity available

2. Professional engineering team and sales team

3. Payment: T/T & Western Union

4. OEM/ODM Supporttable

5. Free samples provided

6. Competitive price and high quality

FAQ:

1. Q: Are you a factory or trading company?

A: We are direct manufacturer located in Xi'an, Shaanxi province, and have our equipment!

2. Q: Are your products customized?

A: Yes,the products in the website are only the common type or the previous types, we can supply the new products according to your requirements or drawings.

3. I do not know how to use your product ?

Do not worry ! We can supply technical guidance together with products.

4. Q: How can I get some samples?

A: Several samples are freely offered for buidling the business long-term relationships and letting our customers believing the quality of our products.

-

High quality Cast magnesium AZ31 billet AZ61A rod AZ80A bar M1A ZK60A cast bar block diameter 90-800mm for extrusion

-

Magnesium Alloy Billet / Rod / Bar diameter 1.2-200mm High strength ASTM specification

-

AZ31 magnesium billet AZ31B magnesium billet AZ31 magnesium alloy billet ASTM B107/B107M-13

-

AZ80 AZ80A AZ80A-F AZ80A-T5 magnesium billet surface peeled Extruded heat treatment AZ80A billet ASTM B107/B107M-13

-

AZ80A-F AZ80A-T5 magnesium alloy billet AZ80A magnesium cylinder rod bar disc ASTM B107/B107M-13 AZ80 magnesium billet

-

Magnesium alloy billet AZ31 AZ61 AZ91 AZ80 ZK60 AM60 Round Bar Diameters 1.6mm - 203mm