|

|

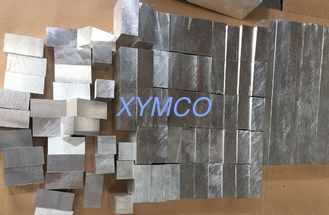

No stress relief Cast AZ91 AZ91D magnesium plate block AZ91E magnesium rod billet AZ91A magnesium bar

Product Details:

Payment & Shipping Terms:

|

| DAMPING: | Absorbs Vibration For Longer Life, While Retaining Dimensional Stability | TOOLING: | 4 To 5 Times Greater Tool Life. |

|---|---|---|---|

| COSTS: | Machine Dry, Without Oil Or Chemicals. | NONMAGNETIC: | Good For Electrical And Computer Applications. |

| STABILITY: | No Stress Relief After Machining; No Warps And Is Dent Resistant. | STRENGTH: | Excellent Strength And Stiffness Per Unit Weight. |

| Modulus Of Elasticity:: | 45 X 109Pa | Electrical Resistivity:: | 92nΩm |

| Thermal Conductivity:: | 76.9Wm-1k-1 |

No stress relief Cast AZ91 AZ91D magnesium plate block AZ91E magnesium rod billet AZ91A magnesium bar

Semi-continuous Cast magnesium alloy billet and slab is manufactured as the starting material for other magnesium products, such as plate, forgings and extrusions. However, it has been frequently found that the cast billet and slab is suitable for machining into prototypes, thus avoiding expensive tooling, and in some cases for production where the size of the finished items is outside economic casting or extrusion dimension or minimum economic production.

Semi-continuous Cast Magnesium Alloy Billet and Slab is supplied to clients on the compositional and homogenized condition.

For AZ91D cast billet: OD 120 – 600mm, length is 2000mm

For AZ91D cast slab: max. 400 x 1200 x 2500mm

Both the billet and slab, we can cut to size as per customer’s requirement

Chemical Composition (%)

Al: 8.3-9.7

Mn: 0.15-0.5

Zn: 0.35-1.0

Si: 0.10

Cu: 0.030

Ni: 0.002

Iron max: 0.005

Mechanical Properties of the cast billet and slab:

Tensile strength: 140Mpa

Yield strength: 100Mpa

Elongation: 2%

Hardness: 63HBW

Density: 1.81g/cm3

We also produce the forged AZ91D blocks, the max. size is 300 x 500 x 1000mm.

Mechanical Properties:

Tensile strength: 250Mpa

Yield strength: 160Mpa

Elongation: 6%

![]()

XIAN YUECHEN METAL PRODUCTS CO., LTD. (XYMCO) is one of the leading manufacturer of magnesium alloy products located in Xincheng Hi-Tech Industry Estate, Xi’an, Shaanxi, China, who is specialized in the development, manufacture and supply of magnesium alloy products worldwide included magnesium tooling plate, magnesium alloy plate, magnesium alloy sheet, magnesium alloy slab, magnesium alloy bar, magnesium alloy billet, magnesium alloy rod, magnesium alloy tube, magnesium alloy pipe, magnesium alloy profile, magnesium welding wire, magnesium alloy extrusion, magnesium alloy stamping, magnesium alloy casting, magnesium alloy forging and semi - fabricated component according to customer’s design.

We comply with the specifications:

GB5153-03, GB5154-04, AMS4377G, ASTM B90/B90M-15, MIL-DTL 32333, MIL-T-38749, QQ-M-44B, ASTM B107/B107M-13 and ASTM B91-97

Material grades: AZ31B, AZ61A, AZ80A, AZ91D, AZ41M, ZK60, AM50, AM60, ZM21, MIA, ME20M, EQ21, WE43, WE54, ZE41, etc.

Our main products and capabilities are as follows:

1. Magnesium tooling plate: Max. Thickness: 300mm; Max. Width: 2000mm; Max. Length: 6000mm

2. Magnesium alloy cast slab: Max. Size: 400 x 1000 x 3000mm

3. Magnesium alloy sheet: Min. Thickness: 0.5mm; Max. Width: 600mm; Max. Length: 2000mm

4. Magnesium cast billet: Min. Diameter 90mm; Max. Diameter: 600mm; Max. Length: 6000mm

5. Magnesium alloy extruded wire: Dia.1.0mm – 8.0mm in spool.

6. Magnesium alloy extruded rod: Min. Dia. 8mm; Max. Diameter: 450mm; Max. Length: 3000mm

7. Magnesium extrusions:

Round tube: Max. OD600mmx thickness 125mm

Square tube: 430 x 430mm

Flat bar: 920 x 160mm

U-Shape: 800 x 300mm

Rectangular: 700 x 200mm

8. Magnesium-Lithium Alloy rod, sheet, plate and tube.

XIAN YUECHEN METAL PRODUCTS CO., LTD. (XYMCO) is able to mass produce LZ91, LA91, LA141, MA18 and MA21 magnesium lithium alloys in the form of rectangular or round shape ingot by vacuum melting techniques, and mass produce MgLi wrought alloys and its products of magnesium lithium alloy slab, magnesium lithium alloy bock, magnesium lithium alloy plate, magnesium lithium alloy sheet, magnesium lithium alloy foil, magnesium lithium alloy strip, magnesium lithium alloy coil, magnesium lithium alloy billet, magnesium lithium alloy rod, magnesium lithium alloy bar, magnesium lithium alloy tube, magnesium lithium alloy pipe, magnesium lithium alloy wire, magnesium lithium alloy profile by casting, forging, extrusion and hot rolling process. XYMCO also produces the customized sizes (non standard sizes) magnesium lithium alloy materials and its products according to customers’ requirements.

NPFC - MIL-M-46130 Magnesium-Lihium Alloy Plate, sheet and forgings (LA141A, LS141A and LZ145A)

Our products already were exported to USA, Japan, Israel, India, Germany, Iran, Columbia, Italy and UK.

Magnesium–Rare Earth Alloy

The beneficial effects of rare earth on the non-ferrous materials in the magnesium alloy are the most obvious. Appropriate content of rare earth can refine the grain size of magnesium and magnesium alloys. The first is to refine casting grain. Rare earth elements refine the mechanism is not the role of heterogeneous nucleation of magnesium alloy casting organizations. The mechanism of rare earth elements on the grain refinement of magnesium and magnesium alloy crystallization forefront of undercooling increases.

Alloying magnesium with rare-earth elements (RE) is used to develop light construction alloys for the applications at elevated and high temperatures. Generally, RE elements in Mg have relatively high solubility decreasing significantly with decreasing temperature. Therefore age hardening is possible in these alloys to improve mechanical properties.

Magnesium-Neodymium, Magnesium-Zirconium, Magnesium-Lanthanum Alloy, Mg-Ce Alloy, Magnesium-Scandium, Magnesium-Gadolinium, Magnesium-yttrium are high purity RE alloys manufactured by XYMCO. As master alloys, they can be used for grain refining, hardening, and improving alloy performance by enhancing properties such as ductility and machinability. Available Magnesium-Rare Earth alloy forms include sheets and plates, discs, rods, tubes, and other shapes. XYMCO can produce Magnesium-Rare Earth alloys in various standard ratios of Mg/RE; Customized Magnesium-Rare Earth alloys compositions are also available. Advanced chemical analysis is available for all Mg-RE alloys by best demonstrated techniques including X-ray fluorescence (XRF), glow discharge mass spectrometry (GDMS), and inert gas fusion.

XIAN YUECHEN METAL PRODUCTS CO., LTD. (XYMCO) R&D the magnesium based Rare Earth Alloys from 2004. They are widely used for aviation, aerospace, machinery, power plant, auto and railway. Following is the available alloys:

| Name | Alloy Grade | Main alloy content (%) | Specification | Inclusion (%) | Form |

| Mg-Nd Alloy | Mg-Nd25 | Nd: 25±2% | HB7264-96 | As per HB7264-96 | Square |

| Mg-Nd30 | Nd: 30±2% | HB7264-96 | |||

| Mg-Zr Alloy | Mg-Zr25 | Zr: 25±2% | HB6773-93 | As per HB 6773-93 | Square, round bar |

| Mg-Zr30 | Zr: 30±2% | HB6773-93 | |||

| Mg-Zr40 | Zr: 40±2% | HB6773-93 | |||

| Mg-Sc Alloy | Mg-Sc | Sc: 2%~10% | As per customer requirement | Square, round bar | |

| Mg-Y Alloy | Mg-Y | Y: 20%~70% | High purity | Less than 100ppm | Round bar |

| Mg-Gd Alloy | Mg-Gd | Gd: 20%~70% | High purity | Less than 100ppm | Round bar |

Both the small quantity and big quantity per order is available

![]()

Other Magnesium based Alloys:

AE811S, ZE41A, WE43, WE54, WE94

Mg-La Alloy; Mg-Sb Alloy; Mg-Ce Alloy; Mg-Sr Alloy; Mg-Er Alloy; Mg-Sn Alloy; Mg-Yb Alloy; Mg-Ir Alloy; Mg-Dy Alloy; Mg-In Alloy; Mg-Re; Mg-Ti; Mg-Re (La); Mg-Co; Mg-Mn; Mg-Si; Mg-Ca; Mg-V; Mg-Fe; Mg-Zn; Mg-Ni; Mg-Al-Sc; Mg-Cu; Mg-Y-Ni; Mg-Al; Mg-Al-Zn.

We also produce special magnesium based master alloys as customer’s requirements.

Our Services:

1. Small order quantity available

2. Professional engineering team and sales team

3. Payment: T/T & Western Union

4. OEM/ODM Supporttable

5. Free samples provided

6. Competitive price and high quality

FAQ:

1. Q: Are you a factory or trading company?

A: We are direct manufacturer located in Xi'an, Shaanxi province, and have our equipment!

2. Q: Are your products customized?

A: Yes,the products in the website are only the common type or the previous types, we can supply the new products according to your requirements or drawings.

3. I do not know how to use your product ?

Do not worry ! We can supply technical guidance together with products.

4. Q: How can I get some samples?

A: Several samples are freely offered for buidling the business long-term relationships and letting our customers believing the quality of our products.

-

ZK60A magnesium alloy plate block disc 300x500x500mm ZK60A-T5 high strength and competitive price and fast delivery

-

AZ31B Magnesium alloy plate, AZ31B rollled plate, polished surface with fine flatness, cut-to-size as per ASTM B90/B90M-15

-

AZ31B ME20M Magnesium alloy plate, polished surface with fine flatness, cut-to-size as per ASTM B90/B90M-15

-

Cast and forged ZK60A-T5 magnesium alloy plate block slab ZK60A-T6 disc high strength competitive price fast delivery

-

ZK60A-T5 cast and forged magnesium alloy plate ZK60A-T6 forged magnesium block disc ZK60A magnesium alloy rod billet bar

-

ALKALI-RESISTANT AZ31B-O magnesium tooling plate AZ31B ASTM B90/B90M-07 vibration testing equipment