|

|

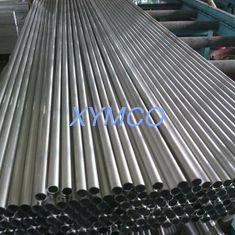

Customized Cold drawn High strength Magnesium pipe AZ31 AZ80 wire bar/rod/billet AZ61 ZK60 Magnesium tubing for sports

Product Details:

Payment & Shipping Terms:

|

| Light Weight: | Density Is 1.78, Less Than Aluminium 33% | Good Strength: | Mechanical Properties Is Higher Than Aluminium 6061 |

|---|---|---|---|

| NONMAGNETIC: | Good For Electrical And Computer Applications | WELDING: | Strong Weldments Up To 95% Of Parent Metal, With Minimal Porosity |

| DAMPING: | Absorbs Vibration For Longer Life, While Retaining Dimensional Stability | STABILITY: | No Warps And Is Dent Resistant; No Stress Relief After Machining |

Magnesium pipe Tube AZ31 AZ80 wire, high strength profile, bar/rod/billet AZ61 ZK60 Customized Magnesium pipe

Xi'an Yuechen Metal Products. Co., Ltd. (XYMCO) - a manufacturer specialized in the magnesium tooling plate, Magnesium alloy plate, magnesium alloy slab, magnesium alloy sheet, magnesium alloy bar, magnesium alloy tube, magnesium alloy billet, magnesium alloy rod, magnesium alloy rod, magnesium alloy pipe, magnesium welding wire, magnesium alloy profile, magnesium alloy forging, magnesium alloy casting, magnesium alloy machining part.

We comply with the specifications: AMS 4377G, AMS 4382, ASTM B90/B90M and ASTM B107.

Material grades: AZ31B, AZ61A, AZ80A, ZK60, AM50, AM60, AZ91, EQ21, EZ33, EV31, WE43, WE54 and ZE41.

Our main products and capacities are as follows:

1. Magnesium tooling plate: Max. Thickness: 300mm; Max. Width: 3000mm; Max. Length: 6000mm

2. Magnesium alloy slab: Max. Size: 400 x 1000 x 2500mm

3. Magnesium alloy sheet: Min. Thickness: 0.5mm; Max. Width: 600mm; Max. Length: 2000mm

4. Magnesium cast bar: Min. Diameter 90mm; Max. Diameter: 600mm; Max. Length: 6000mm

5. Magnesium extrusions:

Round tube: Max. OD 600mmx thickness 125mm Square tube: 430 x 430mm Flat bar: 920 x 160mm

U-Shape: 800 x 300mm Rectangular: 700 x 200mm

6. Magnesium alloy machined part according to customer’s design

7. Magnesium anode as per customer’s design

Our products already were exported to USA, Japan, Israel, India, Germany, Iran, Columbia, Italy and UK. Good quality, good price and good delivery.

Looking forward to your enquiry and hope a prosperous cooperation can be established between us.

![]()

![]()

![]()

Extruded bar, Profile and Machined Components

The process for extruding magnesium wrought material is almost the same as the process for extruding aluminium materials. Most common is direct extrusion without a lubricant.

Cylindrical ingots are heated to 300-400 degrees Celsius (depending on the used alloy) and pressed through dies with manifold cross- sections. This procedure ensures a clean metallic surface and non-porous microstructures that are really important for high-tech materials and special requirements.

The maximum extrusion speed depends on the alloy that’s been used and defines the price. The alloy AZ 31 is easier for extrusion, and the most difficult alloys are for example AZ 80 and ZK 60 The extrusion speed is sometimes more than ten times slower for these alloys.

The special shapes and cross-sections of the magnesium extrusions can be designed with considerable freedom. Extruded shapes are separated into solid and hollow profiles according to the complexity factors and the cross-sections. Full rods, flat bars and shapes without embedded planes belong to the first type, while hollow profiles include one or more completely enclosed cavity or bay region.

The minimum wall thickness is determined by the alloy and form of the profile. For small or medium size profiles in alloy AZ31 the minimum wall thickness is about 1 mm. Wall thickness in multiple walls with bosses, flanges, ribs, slits and indentations can be incorporated into a new designed product to maximize the mechanical properties.

With some of the alloys it’s possible to extrude magnesium on the standard dies that are normally used for aluminium extrusions with a small correction to the die. Because of this there is a wide range of standard profiles (for example flat/angle/rectangular –square and round tubes/ U-shape/H-shape etcetera) that can be extruded without big investments in new dies. The second added value for the customer is that for new designed profiles, he only needs to invest in one single die for extruding profiles in aluminium and magnesium.

After extrusion there are several steps necessary before the extruded profile can be used for constructional components with the required strength for example stretching and special heat treatment.

XYCM’s capacity for the extrusion:

Bar: Max. Diameter: 300mm;

Tube: Max. OD: 600mm x thickness 125mm

Flat bar: 920 x 160mm

U-Shape: 800 x 300mm

Rectangular: 700 x 200mm

Square tube: 430 x 430mm

Max. Length for the above items: 30meter/each

We also can extrude special shape profiles according to customer’s drawings, and we have good machining capabilities.

Applications of our extruded products:

The special characteristics of magnesium such as its light weight and damping capacity make it therefore, a material that is readily used in several different applications.

Automotive

| Engine blocks | Steering column parts | Seat components |

| Bed plates | Brake and pedal brackets | Roof panels |

| Transmission houses | Airbag retainers | Fuel tank covers |

| Transfer cases | Radio frames + heatsinks | Engine hoods |

| Head covers | Radio covers | Rear deck lids |

| Oil pans | Mirror brackets | Full magnesium doors |

| Knee bolsters | Door handles | Wheels |

| Steering wheels | Front ends | Radiator supports |

Sport and Leisure

| Luggage frames | Suit cases | Tennis rackets |

| Bicycle frames | Camping equipment | Snowshoes |

| Mountain bike frames | Eyewear frames | Bull floats |

Common applications

| Cellular phones | Multi-media housings | Camcorders |

| Antenna housing | Camera Housings | Electric shavers |

| Loudspeaker frames | Projector frames | Printers |

| Laptop Housings | Batteries | Headphones |

| Train Seats | Aviation components | Turbine engines |

| Truss constructions | Cargo floors | Powertools |

| Chain saws | Concrete trowels | Wall saws |

| Ladders | Scaffoldings | Shelves |

-

Magnesium pipe AZ31B / AZ80A / AZ61A pipe ZK60A AZ63 AZ91 M1A magnesium alloy pipe tube ASTM standard

-

Magnesium pipe tube ZK60 ZK60A High Strength Magnesium Alloy Profile Magnesium Extruded Tube

-

Magnesium pipe ZK60-F magnesium alloy pipe Magnesium alloy pipe AZ80A-T5 as per ASTM B107/B107M-13

-

Magnesium alloy pipe ZK60 magnesium extruded pipe thick wall Magnesium pipe AZ80A-T5 as per ASTM B107/B107M-13

-

Extruded ZK60-F magnesium pipe ZK60 magnesium alloy pipe AZ61A Magnesium alloy pipe AZ80A-T5 as per ASTM B107/B107M-13

-

ZK60 magnesium pipeZK60A Magnesium alloy pipe ZK60A-T5 as per ASTM B107/B107M-13